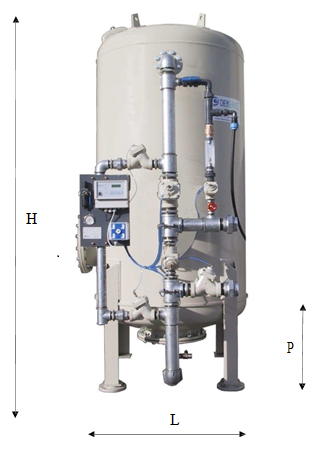

Main components of the plant are:

- Reservoir entirely built in food steel FE 410B painted internally with epoxy bicomponent varnish and externally with polyurethane bicomponent varnish RAL 7032 and is equipped with suitable easy accesses for maintenance operation and load of resins.

- Control valves in cast-iron for membrane (n.o.) equipped with necessary flow regulators.

- Pipes for interconnection of reservoir and valves in galvanized steel.

- The function of the valves is activated thanks to Hydro-pneumatic distributors managed by a control electrical panel with microprocessor logic.

- The prefect hydrodynamic functioning of the reservoir is censure by a distribution system with diffuser nozzles removing at the same time accidental lack of resin.

- All the phases of softening and regeneration are visualized and programmable.

The storage salt container ( optional) in polyethylene. HD with a proper capacity complete with separation grill, water salt, ventilation shaft and hydraulic and floating valve.